Introduction

Superconducting materials are essential foundational materials for generating strong magnetic fields. In applications requiring magnetic fields of several Tesla to tens of Tesla, superconducting wires are often needed to wind the magnets. HTS materials have the potential for large-scale applications in energy, transportation, and large scientific instruments, among other fields.

High-strength superconducting magnets for scientific research mainly include large-diameter high-field superconducting conductors and magnets, interpolated HTS magnets, and CICC (Cable-in-Conduit Conductor) conductors. They can be applied in the fields of large scientific projects, biomedical engineering, national defense, and high-precision scientific instruments. REBCO tapes, which possess higher current-carrying capacity and superior mechanical properties under high magnetic fields, are more suitable for high-field magnets (≥25T) and expected to drive advancements in science and technology.

The core components of particle accelerators and heavy ion cancer treatment system are magnets that accelerate particles to collide or release high-energy rays for research and treatment purposes. REBCO HTS magnets are the preferred choice of the next generation accelerator devices because of their outstanding advantages such as small size, light weight, and no need for liquid helium cooling.

Superconducting wind power generators mainly utilize the zero-resistance characteristic of HTS tapes, replacing copper coils with HTS coils. It has the advantages of smaller size, lighter weight, and lower overall cost, making them suitable for offshore and floating wind turbines. Superconducting wind power generators are among the most promising and ideal energy conversion device, which will further promote the development of the wind power industry and support carbon peaking and carbon neutrality goals.

Traditional heat treatment processes face challenges such as poor heating uniformity, poor temperature controllability, and low energy efficiency. Superconducting DC induction heating technology, based on the zero resistance and high current-carrying characteristics of superconducting materials, uses HTS magnets to generate a background magnetic field, creating a DC air gap magnetic field in the heating area. This method heats the billet by rotating it to cut the magnetic lines of force, generating eddy currents. This innovative solution provides high penetration, high efficiency, high uniformity, and high gradient heating for the metal thermal processing industry.

Since Elon Musk's announcement of the Hyperloop vacuum tube train concept in 2013, the "high-speed transportation" concept has garnered increasing attention. In 2014, Japan began constructing a low-temperature superconducting high-speed maglev line between Tokyo and Osaka, setting a world record with a speed of 603 km/h on the test track. Currently, Germany, Brazil, China, and other countries are researching HTS maglev circular lines. HTS maglev technology uses HTS tape coils as stators or motors, maintaining a high power factor under large air gap working conditions. This technology significantly enhances traction, load capacity, and speed while reducing weight, size, and energy consumption, and lowering cooling costs. As cities rapidly develop, superconducting maglev transport, which is fast, safe, and clean, will provide technological support for the implementation of the "transportation power" strategy.

Application Projects

| Megawatt-Class Superconducting Induction Heater — Jiangxi Lianovation Superconductor Co., Ltd.

Jiangxi Lianovation Superconductor successfully developed the world's first MW-class superconducting induction heating device prototype in 2019 and rapidly evolved into a mass-produced industrial product in 2020. This high-efficiency and energy-saving induction heating furnace can be widely applied in various metal processing and heat treatment fields, realizing nearly 50% energy savings and ultra-uniform heating effects. On April 20, 2023, the world's first MW-class HTS induction heating device was successfully commissioned at Northeast Light Alloy Co., LTD, Heilongjiang Aluminum Corporation of China.

SST has maintained a long-term partnership with Jiangxi Lianovation Superconductor, acting as the core material supplier. From the prototype development phase to the industrial product finalization stage, SST provided all the HTS tapes required, with each device needing over 10 kilometers of 4mm-wide high-performance superconducting material for the core magnet winding of the induction heater. To date, SST has supplied totally hundreds of kilometers superconducting tapes and will continue to supply high-performance superconducting tapes in bulk based on the strategic cooperation agreement between the two parties.

| China's First HTS Electric Levitation Train — CRRC Group

In November 2022, CRRC Changchun Railway Vehicles Co., Ltd. completed the construction of the full-element HTS electric maglev test line. The first levitation operation was successfully conducted in March 2023, thoroughly verifying key technologies for HTS magnets, linear synchronous traction, and other core components of the superconducting electric levitation transportation system. This milestone signifies a major technological breakthrough in China's HTS electric levitation field.

SST has deeply collaborated with CRRC Changchun Railway, serving as the core material supplier for this project by providing all high-performance HTS materials. SST has been deeply involved in the development of various critical components including onboard HTS magnets through years of joint efforts. SST will continue to contribute to the development of larger and faster superconducting electric maglev prototypes in collaboration with the CRRC-led team.

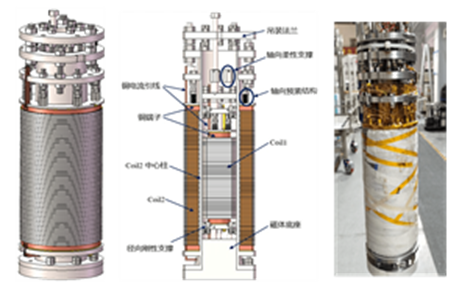

| 24.1T All REBCO HTS Magnet — CAS Institute of Plasma Physics

In October 2022, the team from the Institute of Plasma, Chinese Academy of Sciences successfully energized their independently developed all REBCO HTS magnet to 24.1T. This marks the first domestically produced tightly wound superconducting magnet exceeding 20T. The magnet, immersed in liquid helium, successfully reached a current of 300A, with the central field strength stably maintained at 24.1T.

All the REBCO superconducting tape used in this magnet was provided by SST, demonstrating the excellent performance of domestic REBCO tape under low-temperature and high-magnetic-field conditions. The development of this magnet is of great significance for advancing superconducting materials and magnet equipment in China, laying an important foundation for the subsequent development of high-field scientific devices above 35T.

| Superconducting MRI Magnet — University of Cambridge, UK

In 2021, the University of Cambridge successfully developed a small MRI device specifically designed for cranial imaging to quickly diagnose conditions such as strokes. The magnets inside the device are entirely made with 2G-HTS tapes produced by SST. At an operating temperature of 20K, the device can generate a magnetic field of 1T. The compact and lightweight design allows the device to be quickly moved to the bedside for diagnostic services, offering significant advantages in efficiency and portability.

SST has deeply collaborated with the University of Cambridge, providing all the HTS tapes for the winding of the MRI magnets in this small MRI device.

Add:

Add: Tel:

Tel: Email :

Email :  沪公网安备 31011502002867号

沪公网安备 31011502002867号